Remove any sawdust dirt or debris from the gap to prep it for finishing.

Hiding metal siding joints.

The ends of the boards must be primed to seal against water.

Slide a piece of metal sheeting behind the butt joint.

Joint covers are primed on the outside for easy painting and coated on the inside with an epoxy backer to inhibit.

This way they are hidden from view when looking at the house from the front.

I just installed about 50 of them.

I can t figure out how to flash the bottom joints.

Install the siding along the sides of the house so the exposed ends of the panels face toward the back of the house.

There is a metal j channel and then siding.

There are only a few of these joints but i would like to finish the job.

The joint covers protect the butt joint where two siding planks meet and provide an expansion joint to help prevent siding buckling.

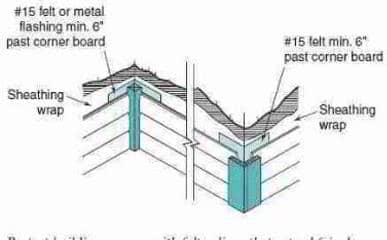

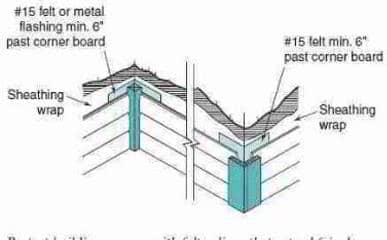

An alternative method installing metal splines helps prevents water intrusion by draining water away quickly.

Use a keyhole or reciprocating saw with a fine tooth blade to remove enough material from one of the pieces of lap siding.

A wraparound lower lip hooks the siding and requires one nail to hold it in place.

A wraparound lower lip hooks the siding and requires one nail to hold it in place.

Create a proper 3 16 space at minimum between the two pieces of siding.

The joint covers protect the butt joint where two siding planks meet and provide an expansion joint to help prevent siding buckling.