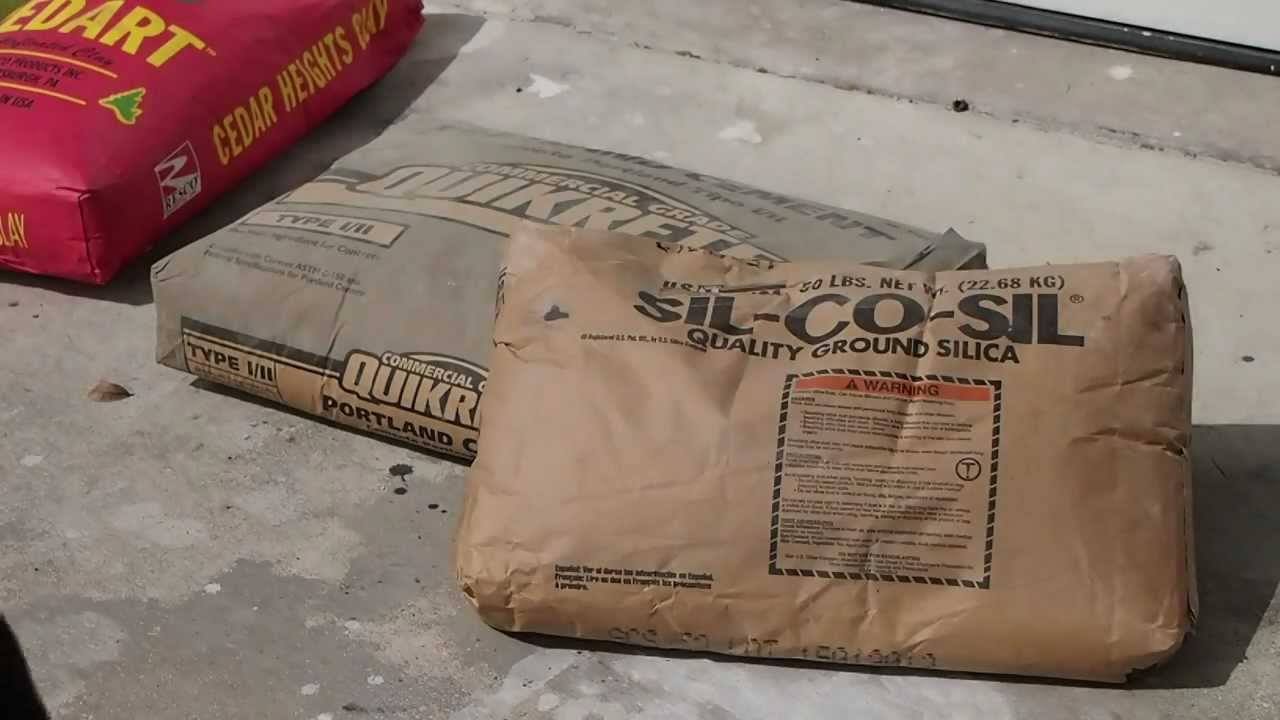

Refractory concrete as refractory castable concrete is consisted of aggregate binder and admixture it is monolithic refractory and is easy to make complex shape of other products.

High heat refractory concrete.

Sakrete high heat mortar is a dry medium duty mortar ideal for setting masonry units in fireplaces fire pits or chimney applications such as setting clay flue liners and parging a smoke chimney chamber.

There is a possibility that it could explode.

Fireproof concrete has several applications for homeowner s and industry.

Commercially fireproof concrete is made by mixing a product known as fly ash a by product of the production of portland cement.

It has high heat resistant characteristics and excellent strength properties.

As one of refractory concrete suppliers rongsheng refractory has the ability to produce high quality refractory concrete for.

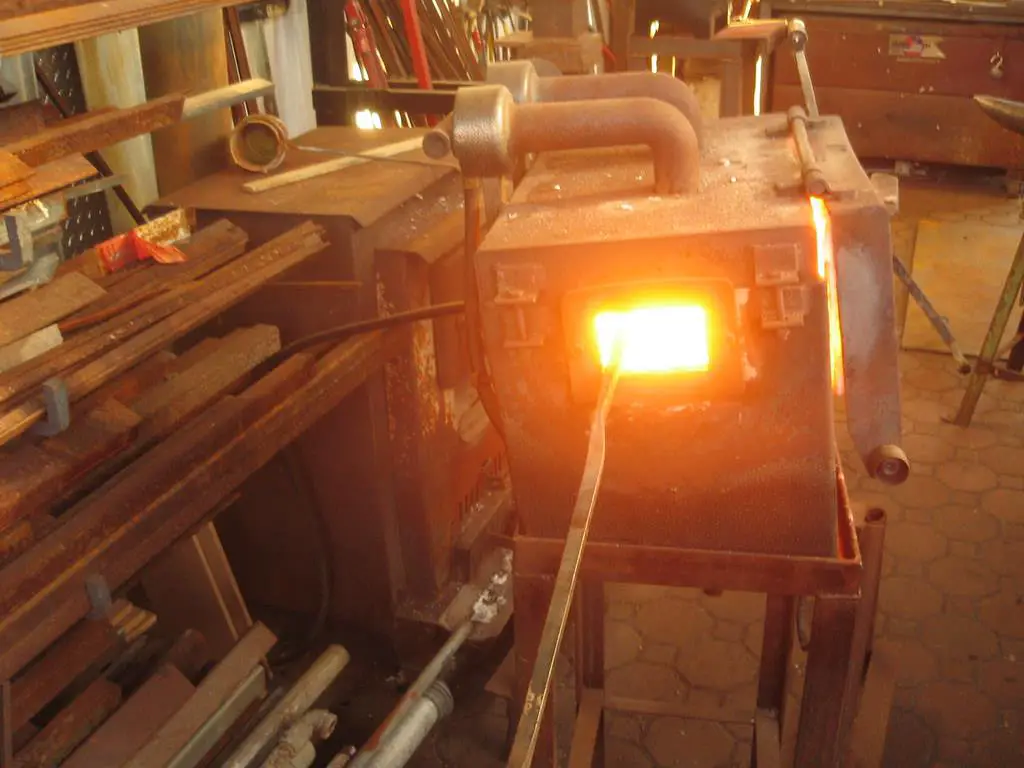

Many wood fired ovens kilns and fireplaces are built with fireproof concrete or other fireproof material known as refractory concrete.

This refractory mortar is designed to successfully withstand high sulphur fuel reducing atmospheres carbon deposition erosion and abrasion.

High heat refractory concrete can be used for lining door wall in furnace or kiln.

Download refractory cement recipe three.

How to make heat resistant concrete type for buildig wood fired pizza ovens and similar applications where heat and heating is present.

Product may be used outdoors a key difference from regular refractory cement does not require heat to cure and may be painted when dry.

Loucast 3000 degree castable refractory is a dense castable refractory mortar rated for 3000 f it is low iron content with high purity.

Sakrete high heat mortar is a dry medium duty mortar ideal for setting masonry units in fireplaces fire pits or chimney applications such as setting clay flue liners and paring a smoke chimney chamber.

To a high heat until you are absolutely certain it is completely dry.

Heat differences in materials.

Refractory concrete mixture ingredients recipe for mixing by hand and concrete in building pizza ovens.

For applications up to 2550 f 1399 c.

It will take several days to dry especially if it is a bigger furnace or.

Minimum 24 hour dry time approximate coverage.

It has high heat resistant characteristics and excellent strength properties.

Casts a block 12 in.